Kaishan Dry-Type 100% Oil-Free Rotary Screw Air Compressor Class 0 Certified

Send email to us Download

Previous:

Class 0 Certification Oil-free Water-injected Single-screw Air compressor

Next:

Dry Screw Vacuum Pump

Dry Oil-Free Screw Air Compressor oil-free air compressor screw type air compressor oil-free

Main unit structural features

| Features | Advantages |

| Original main unit imported from the United States. | Reliable quality |

| Uses two-stage compression. | With a lower pressure ratio, it is more efficient than a single-stage air compressor,achieving the same pressure with less electricity. |

| Compact and exquisite design | Takes up little space. |

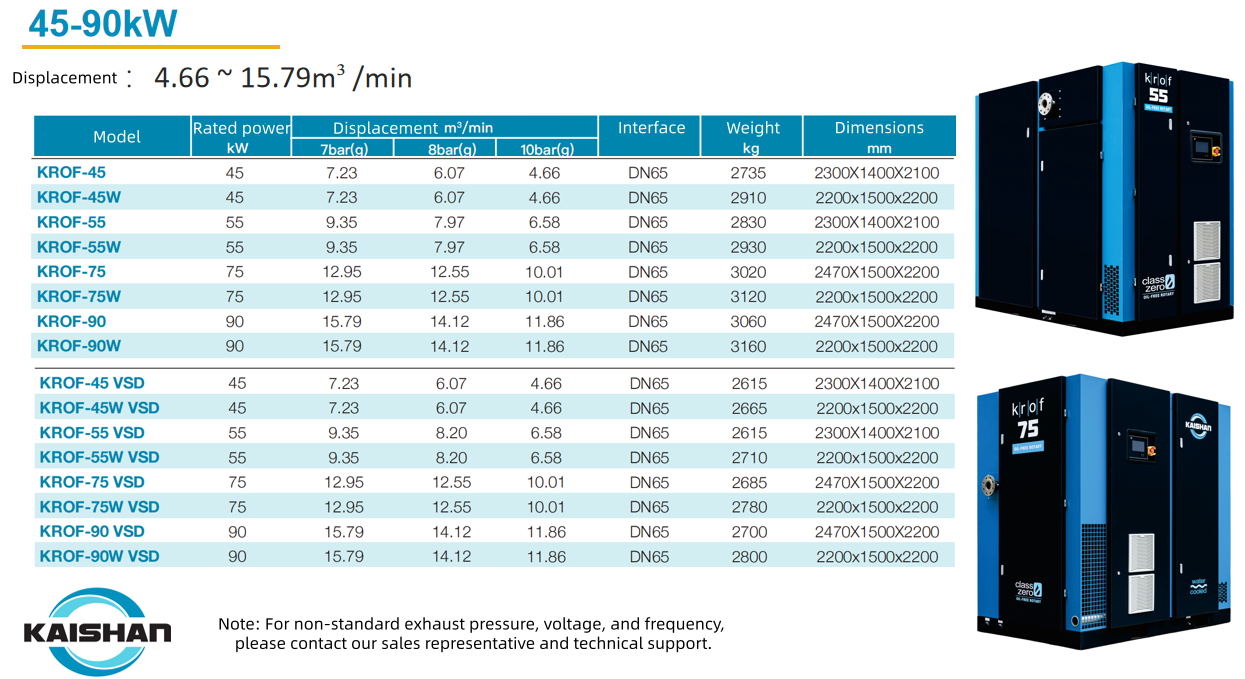

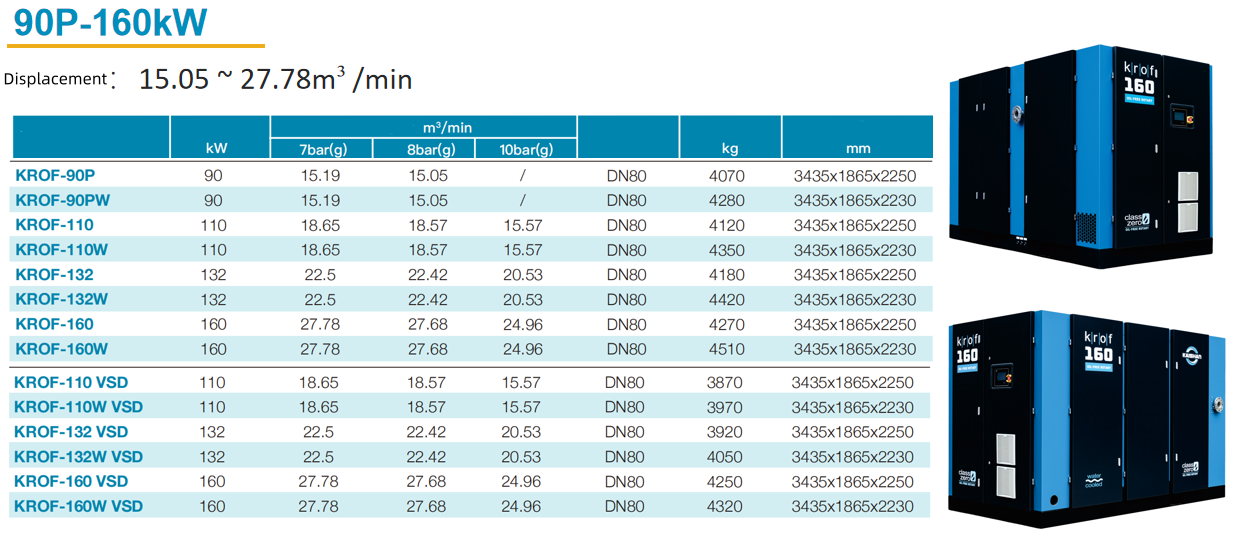

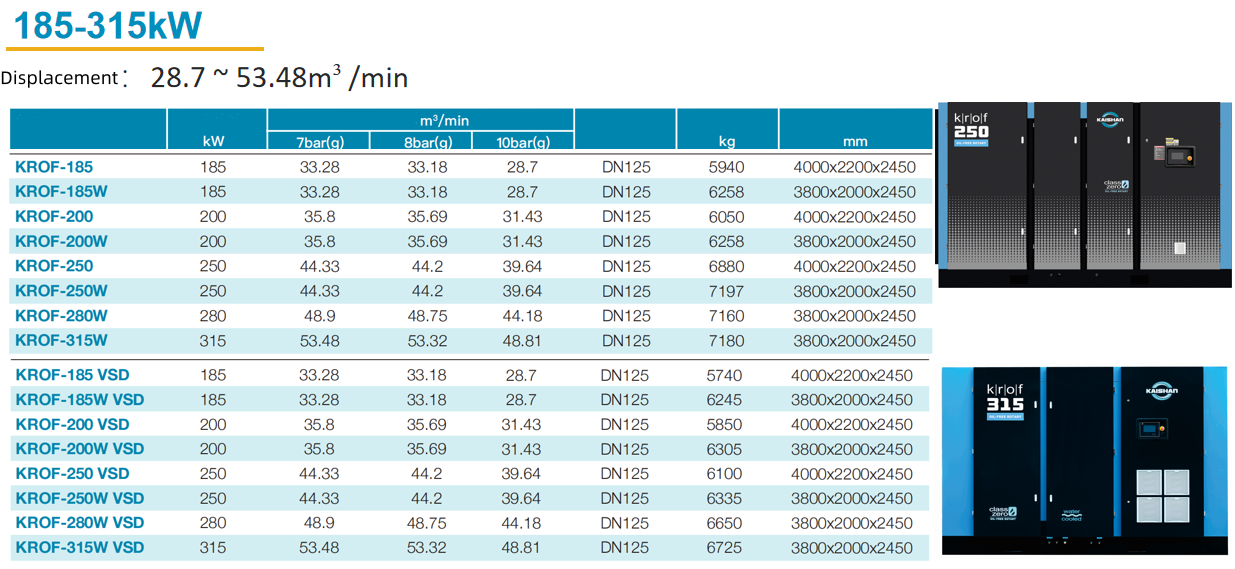

| 90-160kW: 4/5 tooth combination (most efficient and reliable blade combination, low vibration) 45-90kW: 4/6 tooth combination 185-315kW: First stage 5/7 teeth (new technology) Second stage 4/6 teeth |

Most efficient rotor combination |

| Rotor housing with cooling jacket | Effective heat dissipation |

| Multiple gas and oil seals | Ensure oil-free compression. |

Structural characteristics of the complete machine

| Features | Advantages | Benefits |

| Separate design for fan air intake and compressor air intake. | Improve machine energy efficiency | Power saving |

| It features a side-entry and top-exit design. | Cold air is heavier than hot air and stays at lower levels;therefore, cold air entering from below and exiting from above provides the best cooling effect. | Improve overall system cooling performance and extend thelifespan of fans and coolers. |

| Centralized sewage discharge point | Condensate and lubricating oil can be collected centrally. | Waste disposal is convenient and time-saving. |

Core Technological Advantages

- Superior Rotor Coating: The rotor surface utilizes a special ultra-strong Teflon or molybdenum disulfide wear-resistant and anti-corrosion coating, maintaining extremely high volumetric efficiency even under high temperature and high pressure.

- High-Efficiency Two-Stage Compression: The two-stage compression design effectively reduces the pressure ratio and minimizes internal leakage, significantly improving energy efficiency compared to single-stage compression.

- Stainless Steel Rotor and Air Path: Key components are made of stainless steel, completely eliminating corrosion and carbon buildup problems caused by moisture condensation, extending the overhaul cycle of the main unit.

- Physical Isolation Sealing: A combination of labyrinth seals and carbon ring seals creates a physical barrier between the air chamber and the lubrication oil circuit, ensuring that lubricating oil never enters the compression chamber.

Main application areas of the product

1. Automotive industry: Lithium batteries, resistors, automotive paint

2. Electronics industry: Chips, semiconductors, mobile phones

3. Chemical industry: Biotechnology, plastic molding

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp