Class 0 Certification Oil-free Water-injected Single-screw Air compressor

The main unit utilizes a three-line meshing technology, resulting in a long service life and excellent energy efficiency. It also employs a patented non-uniform tooth width technology, further enhancing energy efficiency and extending its lifespan.

Metal parts in contact with water are made of stainless steel, and the star wheel is made of high-grade engineering plastic PEEK. An advanced sealing system is used, integrating mechanical seals, air curtain chambers, labyrinth seals, and bypass channels. The core components of the main unit are precision-machined on dedicated machine tools. The internal structure consists of a screw with six helical grooves, and a pair of flat star wheels on either side forming the working chamber. The rotation of the screw drives the star wheels to perform a cyclical suction, compression, and exhaust rotary motion within the enclosed casing. Each rotation of the screw generates 12 suction, compression, and exhaust cycles. The screw engages with both star wheels simultaneously, balancing the forces on the screw and doubling the displacement, while also resulting in a compact main unit size.

Features

- High Efficiency: Utilizes three-line meshing and non-equal width tooth technology, along with proprietary processing techniques, to overcome the low viscosity of water and maintain high volumetric efficiency. Water spray atomization cooling ensures the compression process is approximately isothermal.

- High Reliability: The main unit operates at a medium speed of approximately 3000 rpm, using rolling bearings. The screw is balanced, resulting in low load.

Metal parts in contact with water are made of stainless steel, and the star wheel is made of high-grade engineering plastic PEEK, which is wear-resistant and corrosion-resistant.

An advanced patented sealing system is used between the main unit’s medium and the bearing chamber, ensuring the reliability of the main unit. - Low noise: During medium-speed operation, the screw is subjected to balanced forces, resulting in low vibration and low noise.

The metal rotor and high-grade engineering plastic meshing transmission contribute to low noise.

Water flowing through the main unit and pipelines effectively reduces vibration and dampens noise.

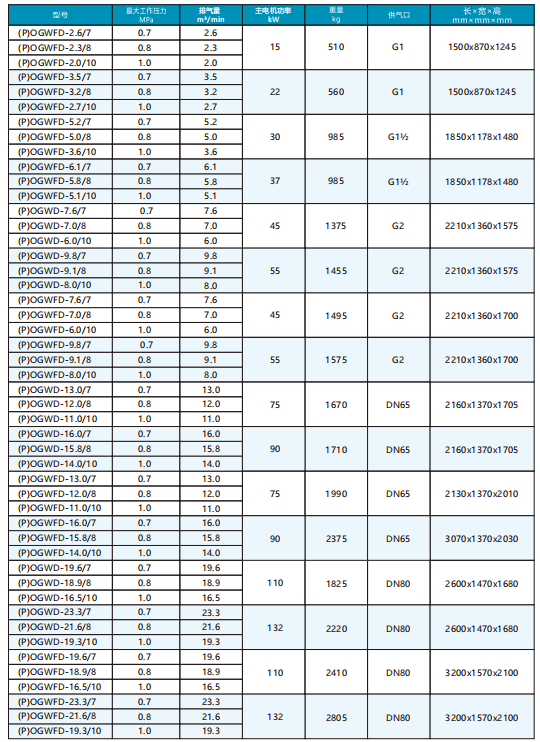

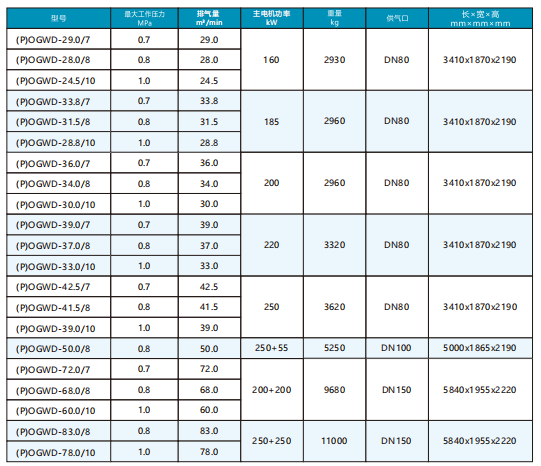

Parameter Range

Power Range: 37~200kW

Pressure Range: 0.3~0.5MPa

Displacement Range: 9.8~43.0 m³/min

For more models, please contact us

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp